Process of Manufacturing

Receiving Fabrics

Receiving Fabrics

Garment factories receive fabric from overseas textile manufacturers in large bolts with cardboard or plastic centre tubes or in piles or bags. The fabric typically arrives in steel commercial shipping containers and is unloaded with a forklift. Garment factories often have a warehouse or dedicated area to store fabric between arrival and manufacturing.

Fabric Relaxing

Fabric Relaxing

“Relaxing” refers to the process that allows the material to relax and contract prior to being manufactured. This step is necessary because the material is continually under tension throughout the various stages of the textile manufacturing process, including weaving, dyeing, and other finishing processes. The relaxing process allows fabrics to shrink so that further shrinkage during customer use is minimized.

Garment manufacturers perform the relaxing process either manually or mechanically. Manual fabric relaxing typically entails loading the bolt of fabric on a spinner and manually feeding the material through a piece of equipment that relieves tension in the fabric as it is pulled through. Mechanical fabric relaxing performs this same process in an automated manner.

Laying

Laying

Laying of paper pattern helps one to plan the placement of the pattern pieces in a tentative manner.

Lay large pieces first and then fit in the smaller ones

It is very economical in laying the pattern and cutting. Even a small amount of material saved in a single layer will help to bring about a large saving of money as hundred’s of layers of fabric will be laid and cut simultaneously.

When laying, the length of the garment should be parallel to the selvedge of the material. Be sure the pattern is placed in the correct grain. Fabrics drape and fall better on the lengthwise grain and also last longer.

Parts that have to be placed on the fold should be exactly on the edge of the fold.

All laying should be done on the wrong side of the material.

When laying the paper pattern, consider the design of the fabric. Care should be taken to see that the design runs in the same direction throughout the garment. All checks and strips should match the seams both lengthwise and across.60

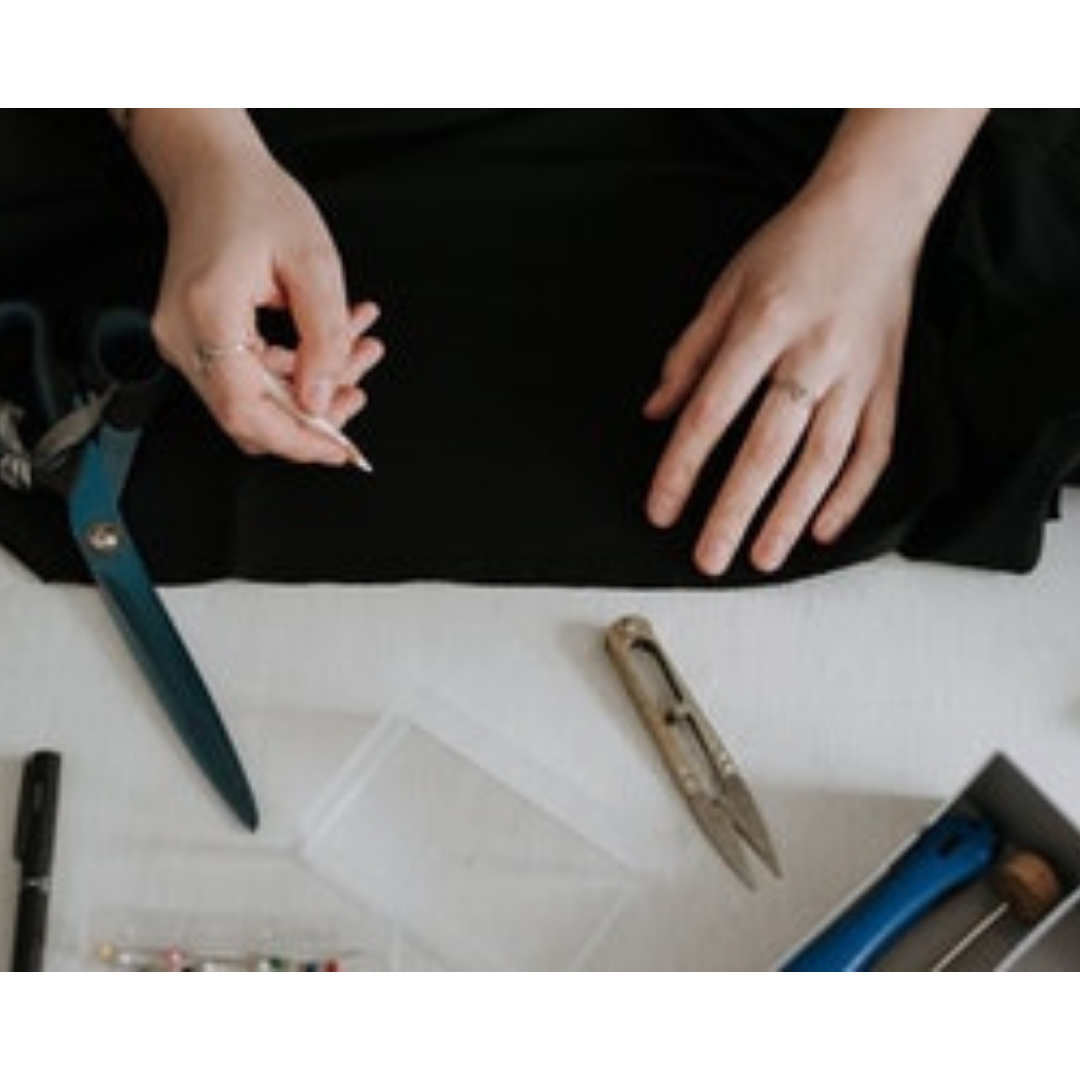

Marking

Marking

This can be a manual or a computerized technique

The marker planner uses full-size patterns and arranges them in an economical manner on marker paper.

This is a specially printed paper having symbols on it which enable the marker planner to visually control the positioning of components according to specified grain lines.

Markers produced on paper are fixed to fabric with pins, staples or on an adhesive paper which is heat sealed to the top layer of the fabric.

Marker planning provides details of the spreads. In the cutting room, the fabric is laid manually or a spreading machine is used to arrange fabric inlays 100 (layers) and markers for the production, any in orders planned. Here planning is done also for fusible, linings, trims, pocketing etc.

The supervisors of marker planner plan and allocates the cut orders to various operations to be carried out in the cutting room.

Cutting

Cutting

This is the major operation of the cutting room when they spread and cut into garments. Of all the operations in the cutting room, this is the most decisive, because once the fabric has been cut, very little can be done to rectify serious defects.

A first planning consideration is whether the totals arrived at in the cutting room are the same as those required to maintain full production in the sewing room and subsequently the planned delivery schedule. Any cloth problems created in the cutting room can affect the output in the sewing room. Assuming all components of fabric, design, and trims are acceptable and correctly planned and cut, the next stage is to extend the cutting room programme to the sewing room.

All cutting operations are carried out by straight knife cutting machines.

Sewing

Sewing

Stitching or sewing is done after the cut pieces are bundled according to size, colour and quantities determined by the sewing room.

Garments are sewn in an assembly line, with the garment becoming complete as it progresses down the sewing line. Sewing machine operators receive a bundle of cut fabric and repeatedly sew the same portion of the garment, passing that completed portion to the next operator. For example, the first operator may sew the collar to the body of the garment and the next operator may sew a sleeve to the body. Quality assurance is performed at the end of the sewing line to ensure that the garment has been properly assembled and that no manufacturing defects exist. When needed, the garment will be reworked or mended at designated sewing stations. This labor-intensive process progressively transforms pieces of fabric into designer garments. The central process in the manufacture of clothing is the joining together of components.

Stitching is done as per the specification is given by the buyer.

High power single needle or computerized sewing machines are used to complete the sewing operation. Fusing machines for fusing collar components, button, and buttonhole, sewing machines for sewing button and buttonholes are specifically employed.

Checking

Checking

It is realistic to assume that however well checking or quality control procedures operate within a factory there will always be a certain percentage of garments rejected for some reason or other. The best way to carry out quality checks is by

Establishing a standard as a criterion for measuring quality achievement.

Production results can be measured and compared to the planned quality standard.

Corrective measures to be carried out if there are any deviations in the plans.

Ideally, any system should detect possible deviations before they occur through forecasting. Work produced with minus defects will produce quality products, enhance economy and productivity.

Fusing & Pressing

Fusing & Pressing

Fusing and pressing are two processes which have the greatest influence on the finished look of a garment. Fusing creates the foundation and pressing put the final seal of quality on the garment.

After a garment is fully sewn and assembled, it is transferred to the ironing section of the facility for final pressing. Each ironing station consists of an iron and an ironing platform. The irons are similar looking to residential models but have steam supplied by an on-site boiler. Workers control the steam with foot pedals and the steam is delivered via overhead hoses directly to the iron. In most facilities, the ironing platforms are equipped with a ventilation system that draws steam through the ironing table and exhausts it outside the factory. The basic components of pressing are:

Steam and heat are necessary to relax the fabric and make it pliable enough to be moulded by manipulation.

Pressure: when the cloth has been relaxed by steam, the pressure is applied which sets the fibres into their new positions.

Drying: After the application of steam and pressure, the component or garment must be dried and cooled so that cloth can revert to its normal condition. This is done by a vacuum action which removes surplus water from the fabric and at the same time cools it. For some pressure operations hot air or infrared heating is used instead of vacuum for drying